- Series of rigid pipework and adaptors

- Adaptors provide 30 degrees for alignment

- Pumping capacity up to 40m3/hr

- Able to pump liquid to 1,000,000 cst

- Steel or aluminium

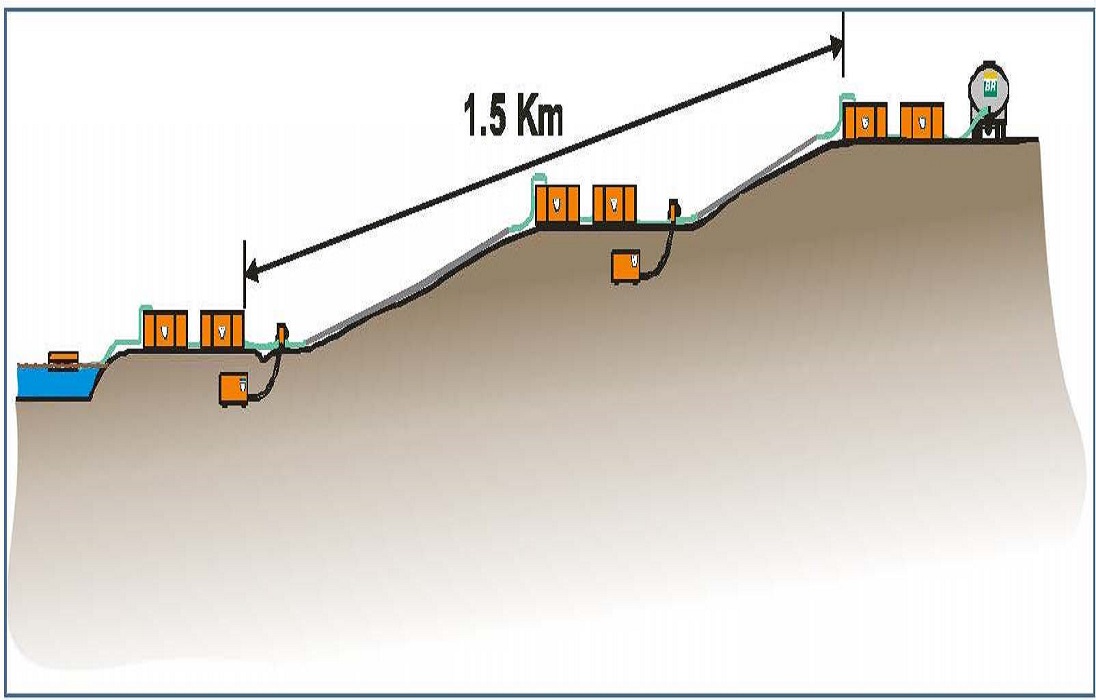

- Distances of up to 1.5km

Our Mini Pipeline system is a revolutionary product that addresses the common problem of transportation of recovered product during an oil spill response operation.

An obstacle that is commonly encountered is the requirement to move recovered oil from a recovery site or a spill on land in a remote location, where contaminated liquid needs to be pumped to a different location for access by equipment such as vacuum trucks.

The Vikoma Mini Pipeline system has the ability to solve this issue. It has the capability to move liquid over distances of up to 1.5km using a combination of decanting tanks and highly efficient positive displacement lobe pumps. The Vikoma Mini Pipeline system also uses a series of rigid pipework with special adaptors that allow a 30 degree alignment to adapt to even the most uneven terrain. The local connections between rigid pipework and tanks are flexible to allow connections to the pumps and valves to be done on-site.

As safety is always a top priority, the Vikoma Mini Pipeline system can be fitted with an auto shutdown device and exhaust spark arrestor to enable safe running in extreme oil spill response environments.

Our pipeline systems have proven popular for moving oils and other liquids from areas which are difficult to reach, such as forests, tundra, marshes and shorelines.

Product Description

- Land

Benefits

- Move oils and liquids over a km from remote locations

- Suited to uneven terrain and remote locations

- Connections to pumps and valves can be made on-site

- Can run dry without causing damage

- Small pumps with high capacity for ease of handling

- Fitted with automatic shutdown devices for safety

- Proven technology with track record for reliability

- Distance can be increased with additional pumps